The Revolutionary Impact of Bakelite: Pioneering Synthetic Plastics

Written on

Chapter 1: Understanding Plastics

Plastics refer to materials that can be molded into various shapes. The term "plastic" originates from the ability of synthetic materials to exhibit a soft, malleable quality during their production process, allowing them to be shaped and later hardened.

Plastics are not a recent phenomenon; natural plastics have been integral to human history. These include resins and gums extracted from tree trunks, which have been historically utilized as sealing wax. Rubber, derived from natural resins, and clay, which serves as a natural plastic for pottery, are additional examples.

Both glass and shellac are classified as natural plastics. Shellac, a resinous substance created by insects in certain regions, has been employed as varnish for centuries. Additionally, amber has been used primarily for decorative purposes. Other natural plastics include pitch, rosin, and tar.

In 1909, Dr. Leo Hendrick Baekeland, a Belgian chemist, made a groundbreaking discovery: when phenol and formaldehyde react, they create a resin that solidifies upon cooling. This resin can be ground into a powder, heated, and molded, where it retains the shape of the mold once set.

This process creates a durable plastic that does not revert to a soft state upon reheating, thus producing a material that resists burning. The resulting product, known as Bakelite, is now a trademark of the Union Carbide Company, although similar products exist under various other names.

Phenol, a by-product of coal distillation, is primarily synthesized from benzene, while formaldehyde is a colorless gas produced through the oxidation of methanol or low-boiling petroleum gases.

The invention of Bakelite marked a pivotal moment in the growth of the plastics industry, providing a valuable plastic resin. It found immediate applications in the burgeoning electrical sector as an insulating material and inspired many innovators to explore new types of plastics and applications.

Video: Bakelite: The First Synthetic Plastic - YouTube

Discover the significance of Bakelite, the pioneering synthetic plastic that transformed the materials landscape.

The price of Bakelite ranges from 20 to 93 cents per pound, influenced by the materials blended with it. It exhibits water and acid resistance in most situations and can be crafted into both flat sheets and complex, solid forms. It can be worked with tools similar to wood or metal, is lighter than both, and is resistant to corrosion.

Bakelite's applications are extensive and include:

- Paneling

- Tabletops

- Costume accessories

- Gears

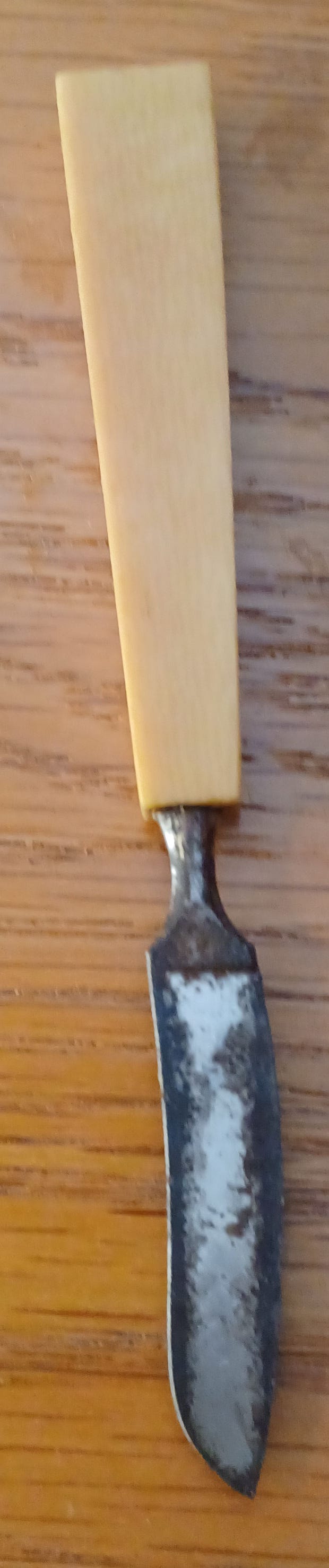

- Handles

- Fixtures

- Lenses

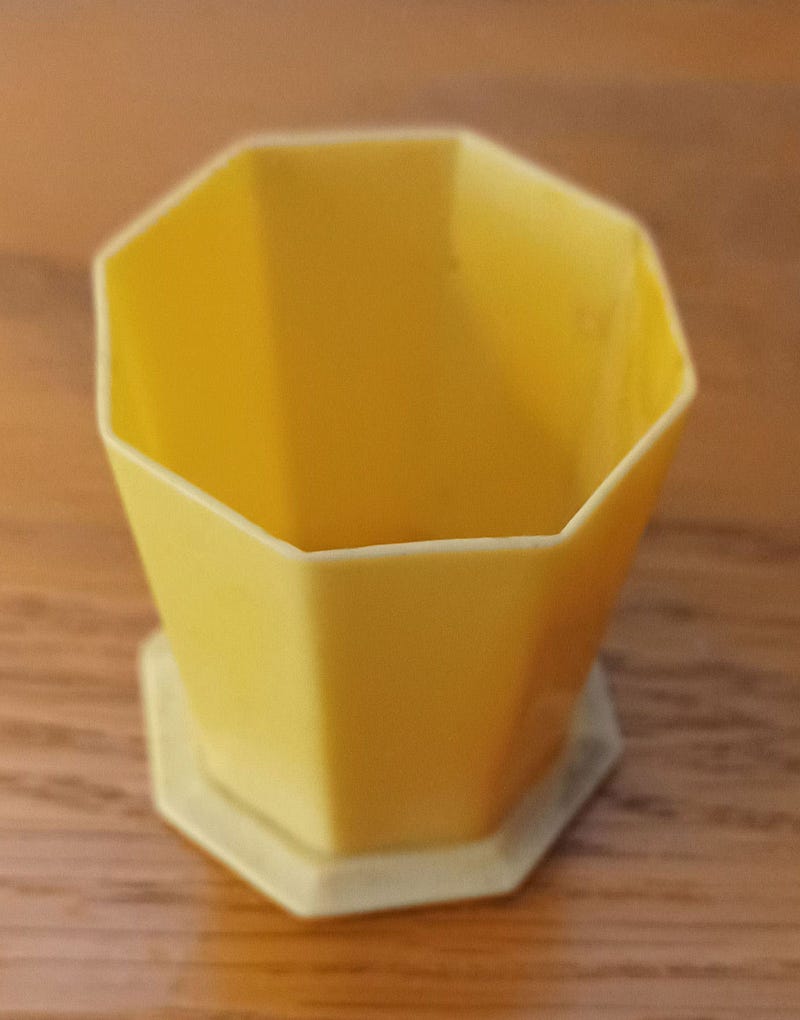

- Tumblers and dishes

- Food packaging and beverage cases, with grease-resistant paper coatings

- Piano and organ keys

- Telephone components

- Bristles

- Batteries

- Film

- Pipes and fittings

- Insulation for wires and cables

- Weather stripping

- Exterior siding

- Rain gutters and downspouts

- Raincoats

- Baby clothing and toys

- Bottles

- Shoe soles

- Draperies and shower curtains

- Garden hoses

- Inflatable toys

- Surgical implants

- Safety eyewear

- Drum covers

- Molded parts for appliances and automobiles

- Switches

- Circuit breakers

Thank you for exploring this fascinating topic.

Amy Potter

Chapter 2: The Announcement of Bakelite

Video: 5th February 1909: Bakelite, the world's first synthetic plastic, announced by Leo Baekeland

Learn about the historic announcement of Bakelite and its transformative role in the development of synthetic materials.